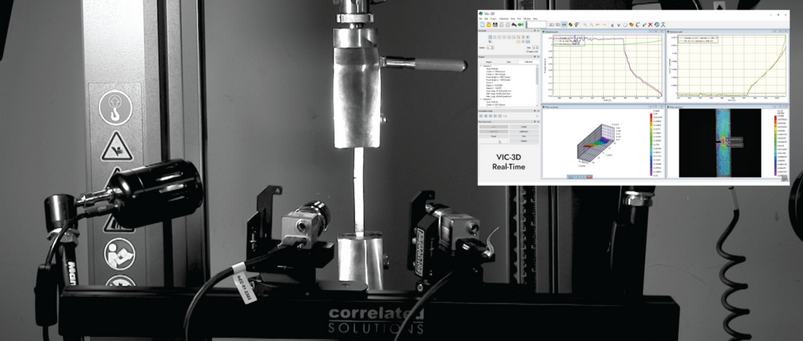

VIC-Gauge uses our optimized 2-D and 3-D correlation algorithms to provide real-time displacement and strain data for mechanical testing.

Think of this tool as a set of virtual strain gauges: Data can be retrieved for multiple points and plotted live against analog load inputs. Results are saved for every analyzed point, and full images may be saved for full-field analysis in VIC-2D or VIC-3D.

Real-time analog output is also available, allowing strain-controlled tests with a completely noninvasive strain measurement method. VIC-Gauge can measure arbitrary displacements and strains from 50 microstrain to 5000% strain and above, for specimen sizes ranging from 5m.

Because the setup is simple, requiring only a single camera imaging the specimen, the VIC-Gauge system can easily be integrated with almost any tensile test frame. No special illumination or lasers are required.

Our VIC-Gauge system is widely used for material testing of compliant materials such as polymers, rubber, or biological tissue.

The system is capable of real-time strain measurement and can be interfaced with standard tension/compression test frames and controllers.

For high strain rate testing, we offer VIC-Gauge systems capable of 100,000 samples per second (post-processing).